Navigating the Clinical Analyzer Market: What Every Laboratory Needs to Know

November 24, 2025

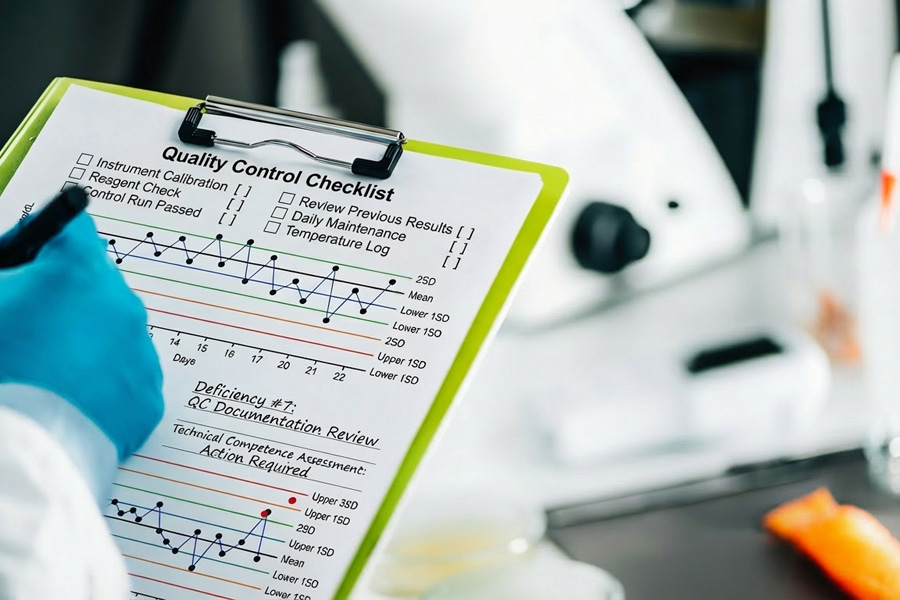

Common COLA and CAP Inspection Deficiencies

January 27, 20262026 Laboratory Budgets

Planning Your 5 Best Investments

As the year comes to a close, laboratories are working on their spending plans for 2026. The decision made now will shape operational efficiency, compliance status, and the potential for a positive bottom line over the next twelve months and beyond.

Everyone is facing the same challenges: reagent costs are climbing, qualified staff remain difficult to recruit and retain, regulatory review remains strong, and reimbursement uncertainty makes revenue projections challenging. Against this backdrop, every dollar in your budget needs to work harder.

At Laboratory Management Consultants, we’ve guided hundreds of laboratories through budget cycles and operational decisions. We’ve seen which investments deliver genuine returns and which become expensive regrets. In this article, we’ll take a look at five strategic investments where laboratories consistently see the strongest ROI.

1. Part-Time Laboratory Director Services

Cut Director Costs by 40-60% While Maintaining Full Compliance

For many small to mid-sized laboratories, the full-time laboratory director salary represents one of the largest line items in the annual budget. A qualified director with appropriate credentials commands $120,000-180,000 annually in salary alone, plus benefits that can add another 25-35% to total compensation costs. That’s a significant investment. For laboratories processing fewer than 500 tests daily, it’s often more capacity than operations require.

Part-time directorship through LMC typically costs 40-60% less than a full-time hire while maintaining complete CLIA compliance. The math is straightforward: laboratories redirect $50,000-80,000 in annual savings toward equipment upgrades, test menu expansion, or simply improved margins.

When Part-Time Directorship Makes Sense

The volume threshold where part-time directorship becomes attractive varies by test complexity, but laboratories running fewer than 500 tests daily generally find part-time arrangements more cost-effective. CLIA regulations specify different director qualification requirements based on test complexity:

- Waived testing: Directors need minimal specific credentials, though qualified oversight still improves quality.

- Moderate complexity: Directors must hold appropriate doctoral degrees or meet alternative qualification pathways with documented experience.

- High complexity: Directors require board certification in anatomic or clinical pathology, or meet specific alternative requirements under CLIA.

Part-time arrangements work well when structured properly. The director maintains meaningful involvement in laboratory operations through regular remote oversight, periodic on-site visits, active participation in quality management decisions, and availability for critical issues. LMC’s part-time directors provide this engagement while serving multiple client laboratories efficiently.

The ROI Calculation

Consider a physician office laboratory currently paying $150,000 annually (salary plus benefits) for a full-time director. Switching to LMC’s part-time directorship at $60,000-75,000 annually frees up $75,000-90,000. That’s enough to fund a new analyzer, expand your test menu into higher-margin testing, or simply improve profitability during uncertain reimbursement times.

2. Preventive Equipment Maintenance Contracts

Avoid $15,000-$25,000 Emergency Repair Bills

Laboratories often view service contracts as optional expenses. They’re nice to have when budgets allow, easy to cut when they don’t. This short-term thinking creates long-term problems. We’ve seen too many laboratories face $15,000-$25,000 emergency repair bills because they skipped preventive maintenance to save a few thousand dollars annually.

The true cost of analyzer downtime extends far beyond the repair invoice. Every day your primary chemistry analyzer sits idle, you’re losing $500-$1,000 in revenue from tests you can’t run. You’re paying premium prices for rushed send-out testing. You’re disappointing referring physicians who expect reliable turnaround times. And your staff has to manage the chaos of turning away walkins while rescheduling patient appointments.

What to Budget

Plan to allocate 8-12% of equipment value annually for preventive maintenance. For a $50,000 analyzer, that’s $4,000-6,000 per year. That’s a fraction of what a single major repair costs. This investment delivers 3-5x ROI through avoided emergency repairs, reduced downtime, extended equipment lifespan, and maintained accuracy that protects your accreditation status.

Manufacturer vs. Third-Party Service

Manufacturer service contracts offer direct access to OEM parts and factory-trained technicians, but they come at premium prices. Third-party service providers can deliver comparable coverage at 20-40% lower cost, though you’ll want to verify their technicians’ training and parts sourcing.

For laboratories considering used equipment purchases, factor service contract availability and cost into your total cost of ownership calculations. That bargain-priced refurbished analyzer becomes less attractive if service contracts are unavailable or prohibitively expensive.

3. Customized Policy & Procedure Manual Development

Prevent $25,000+ in Remediation Costs

Document control deficiencies are among the most frequently cited findings in CAP and COLA inspections, often ranking in the top deficiencies. That’s a big number, and shows a common problem: laboratories rely on generic template manuals that don’t match their actual workflows.

Surveyors can tell when your SOPs don’t reflect what happens at the bench. They ask technicians to explain procedures and compare those answers to your documentation. When there’s a mismatch, you have findings. Accumulate enough findings, and you face corrective action plans, potential probationary or conditional accreditation, or—in severe cases—suspension of certification.

The Real Cost of Generic Templates

A generic template might cost a few hundred dollars, but the remediation costs when it fails inspection run $25,000 or more. You’ll spend on consultant fees to fix deficiencies, staff overtime for rushed documentation updates, and risks to reimbursement in cases of serious, uncorrected noncompliance

Investing $3,000-$8,000 in customized P&P manuals prevents these problems. LMC’s manual development service includes workflow analysis to understand how your laboratory actually operates, SOP customization that reflects your specific instruments, staffing, and test menu, staff training on proper documentation practices, and document control systems that keep everything current.

Beyond Compliance: Operational Benefits

Good documentation delivers benefits beyond passing inspections. New staff onboard faster when procedures are clear and accurate. Quality control failures decrease. Inspections become less stressful when your team can confidently answer surveyor questions. And when issues arise, you have defensible procedures that demonstrate your commitment to quality.

4. Strategic Equipment Upgrades

Right-Size Your Investment for Maximum Payback

Equipment decisions shape your laboratory’s capabilities for years. The key is matching investment to actual operational needs. It’s not about buying the biggest or most impressive analyzer. The goal is selecting equipment that delivers the best return for your specific situation.

Analyze Volume Trends Before Purchasing

Start with honest assessment of your test volume trends. A common mistake is buying equipment sized for current volume when you should plan for 1.5x projected growth over two years. Underestimating leads to bottlenecks and rushed additional purchases. Overestimating means paying for throughput you’ll never use.

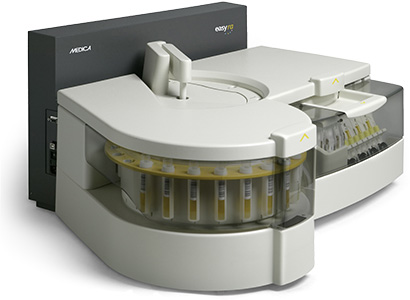

For small to mid-sized laboratories, compact benchtop analyzers often deliver the best value. The Medica EasyRA, for example, offers throughput up to 300 tests per hour (or up to 480 tests per hour including ISE). It doesn’t require dedicated water lines or drainage, which is critical for facilities in leased medical office space where renovation costs quickly eliminate equipment savings.

Timing Matters

Align equipment purchases with your accreditation cycle. Installing new analyzers weeks before a CAP or COLA inspection creates validation pressure and rushed implementation. Plan major equipment acquisitions 3-6 months before inspections to allow proper validation studies, staff training, and workflow integration.

Refurbished vs. New: Making the Right Choice

Quality refurbished equipment can deliver 40-60% savings compared to new, but only when properly vetted. Demand complete service histories, verify reagent availability and pricing, and factor validation requirements into your timeline. Used equipment isn’t grandfathered under CLIA: you must validate every analyzer as if it were new.

LMC actively buys and sells laboratory equipment, giving us real-world insight into the used market. We know which platforms retain value, which have service support issues, and which represent genuine opportunities versus expensive mistakes.

High-Margin Opportunities

Consider test menu expansion that brings high-margin results in-house. Pain management clinics adding LC-MS toxicology capabilities can capture significant revenue currently going to reference laboratories. The Sciex 3200 and 4500 platforms provide proven reliability for therapeutic drug monitoring and definitive quantitation, and quality refurbished units offer entry points for laboratories not ready for new equipment investment.

5. Accreditation Preparation & Compliance Support

Year-Round Compliance Beats Last-Minute Scrambling

Too many laboratories operate in crisis mode around accreditation. They scramble for 3-6 months before inspections, creating stress and exposing gaps that could have been addressed proactively. This reactive approach costs more than year-round compliance support.

Mock Surveys: Find Problems Before Inspectors Do

Mock surveys represent one of the smartest compliance investments you can make. At $2,000-$5,000, a thorough mock inspection identifies deficiencies while you still have time to fix them. Compare that to the $20,000+ in remediation costs, consultant fees, and potential reimbursement impacts after a failed actual inspection.

LMC’s mock surveys use current CAP, COLA, and CLIA checklists. We don’t just identify problems, we help you understand why they’re problems and how to implement lasting solutions. Our consultants have conducted hundreds of inspections and know exactly what surveyors look for.

Ongoing Regulatory Monitoring

CLIA, CAP, and COLA requirements evolve constantly. Staying ahead of regulatory changes prevents surprises during inspections. LMC monitors regulatory developments and alerts clients to changes affecting their operations. This proactive approach keeps you compliant without requiring your staff to track every regulatory update.

For New Laboratories

Laboratories facing first-time accreditation benefit enormously from experienced guidance. The accreditation process has specific requirements, timelines, and costs that catch unprepared laboratories off guard.

CLIA certification typically takes 60-120 days for a Certificate of Waiver, with Certificates of Compliance or Accreditation requiring 120 days or more depending on inspection scheduling. Costs range from approximately $250–$12,000 biennially based on certificate type, test volume, and schedule (with additional survey fees possible for Certificates of Compliance).

LMC guides new laboratories through every step: application completion, personnel qualification documentation, quality system development, inspection preparation, and ongoing compliance maintenance.

LMC: Your Partner in Strategic Budget Decisions

Budget planning isn’t about finding places to cut costs—it’s about allocating resources where they deliver the greatest returns. The five investment areas outlined here consistently provide measurable ROI for the laboratories we serve:

- Part-time laboratory director services that save 40-60% while maintaining compliance

- Preventive maintenance contracts that deliver 3-5x ROI through avoided emergencies

- Customized P&P manuals that prevent $25,000+ remediation costs

- Strategic equipment upgrades matched to your actual operational needs

- Year-round accreditation support that replaces expensive crisis-mode scrambling

What sets LMC apart is our integrated approach. Unlike equipment vendors who only care about sales, or consultants who disappear after delivering reports, we provide ongoing support across all five investment areas. From director staffing and equipment sourcing to documentation development and accreditation preparation, we help laboratories maximize every budget dollar.

Take the Next Step

Ready to make 2026 your laboratory’s most efficient year yet? Contact Laboratory Management Consultants today at (606) 487-0523 or email tpace@emaillmc.com for a free budget planning consultation.

For laboratories considering equipment purchases or sales, visit our equipment services page at

https://laboratorymanagementconsultants.org/buying-and-selling-lab-equipment/

Don’t let another budget cycle pass without strategic planning. With the right investments in the right areas, your laboratory can improve operations, maintain compliance, and strengthen your bottom line.

Medica EasyRA

Thermo Fisher Indiko Plus

Abbott ImmTox 270

The 3200 QTRAP system

The Pictus 500