2026 Laboratory Budgets | Planning 5 Best Investments

December 16, 2025Common COLA and CAP Inspection Deficiencies

How to Avoid the Top 10 Findings

The beginning of a new year is a good time to assess your laboratory’s inspection readiness.

With many facilities facing spring surveys, January brings renewed focus on operational improvements and compliance preparation. Rather than waiting for surveyors to identify problems, you can be proactive. Use the first quarter of the year to strengthen your laboratory’s quality systems and address potential deficiencies before they become citations.

At Laboratory Management Consultants, we’ve guided hundreds of laboratories through CAP and COLA inspections. We understand the anxiety that accompanies survey preparation, but we’ve also learned that inspections aren’t necessarily adversarial. They’re opportunities to validate your quality systems and demonstrate your commitment to patient care. More importantly, the vast majority of deficiencies are easily preventable with proper preparation and good compliance practices.

This article examines ten of the most common deficiencies across CAP and COLA inspections in our consulting experience, explains why surveyors focus on these areas, and provides specific prevention strategies you can implement before inspection.

Understanding CAP and COLA Inspection Focus Areas

The College of American Pathologists (CAP) publishes annual data on the most frequently cited deficiencies across its accredited laboratories. This data reveals repeated patterns that laboratory managers can use to prioritize their compliance efforts. In recent data (for example, 2023 showed procedure manual deficiencies topping the list with 741 citations, followed closely by activity menu inaccuracies (712 citations) and instrument comparability issues (694 citations)). 2024 data showed the same problems, with only minor shifts in order. When 2025 data is fully available, it is likely to be very much the same.

COLA, the Commission on Office Laboratory Accreditation, serves as a CMS-approved accrediting organization with particular focus on physician office laboratories and smaller clinical facilities. While COLA publishes less detailed public data than CAP, cross-agency analyses confirm substantial overlap in deficiency patterns. Personnel competency assessment, proficiency testing handling, and procedure manual compliance seem to always appear as top concerns for both organizations.

The key difference lies in approach. CAP employs a peer-review model with practicing laboratory professionals conducting inspections, while COLA emphasizes an educational approach, working as consultants to help laboratories understand not just what needs improvement, but why and how to implement solutions. Both organizations, however, enforce the same underlying CLIA standards, which is why deficiency patterns align so closely.

1. Procedure Manual Deficiencies

Why Surveyors Focus Here

Procedure manuals ranked as the number one deficiency in CAP’s data for good reason. Your standard operating procedures form the foundation of consistent, accurate testing. When SOPs are outdated, missing required annual reviews, or don’t match actual bench practice, surveyors know that quality control is at risk. They’ll ask technicians to explain procedures and compare those answers to your written documentation. Mismatches raise immediate red flags.

Prevention Strategies

Implement an annual review process that involves the staff who actually perform the testing. Use electronic document control with version tracking and automated review reminders. Archive obsolete procedures properly rather than simply deleting them. Ensure bench staff can access current SOPs easily, whether through electronic systems or well-organized physical binders, and maintain downtime backup plans for electronic access. Most critically, walk through your laboratory periodically to verify that what happens at the bench matches what’s written in your procedures.

2. Personnel Competency Assessment Inadequacies

Why Surveyors Focus Here

Competency assessment often leads citations across accrediting agencies. CLIA requires laboratories to evaluate personnel competency using six specific elements: direct observation, monitoring recording and reporting of results, review of intermediate test results, review of QC records, assessment of problem-solving skills, and assessment of test performance through testing previously analyzed specimens. Incomplete assessments, improper timing, or unqualified assessors all trigger citations.

Prevention Strategies

Use CAP or COLA competency assessment templates to ensure you’re covering all six required elements. Assess new employees semiannually during their first year, then annually thereafter. Cover all test systems each person performs, including pre-analytical, analytical, and post-analytical phases. Integrate competency assessment into routine supervision rather than treating it as a separate annual event. Document everything thoroughly, including who performed the assessment and their qualifications to do so.

3. Proficiency Testing Deficiencies

Why Surveyors Focus Here

Proficiency testing provides external validation of your laboratory’s analytical accuracy. When PT failures occur, surveyors want to see thorough investigation, root cause analysis, and effective corrective action. Missing attestation statements, inadequate failure investigations, or handling errors that compromise PT integrity all generate citations. PT deficiencies are often in the top five across both CAP and COLA inspections.

Prevention Strategies

Standardize your PT investigation process with documented procedures for every unacceptable result. Ensure the laboratory director reviews every PT event, not just failures. Document the potential impact on patient results when failures occur and what corrective actions were taken. Maintain signed attestation statements confirming that PT samples were tested in the same manner as patient specimens. Use PT toolboxes and resources from your accrediting organization to strengthen remediation processes.

4. Activity Menu Inaccuracies

Why Surveyors Focus Here

Your activity menu must accurately reflect all testing done at your lab. This isn’t just administrative paperwork; it ensures your accreditation scope matches your actual operations. Adding new tests without updating your activity menu, or continuing to list discontinued tests, creates compliance gaps. In CAP’s data, activity menu issues rated as the second most common deficiency.

Prevention Strategies

Tie activity menu updates directly to your new test implementation process. Before bringing any new test online, verify it’s been added to your activity menu. Conduct quarterly audits comparing your menu to actual testing performed. Remove discontinued tests promptly. Assign specific responsibility for activity menu maintenance to ensure updates don’t fall through the cracks during busy periods.

5. Instrument/Method Comparability Issues

Why Surveyors Focus Here

When laboratories use multiple instruments or methods to perform the same test, results must be comparable. Patients shouldn’t receive different results depending on which analyzer happened to run their sample! CLIA requires semiannual verification of comparability for nonwaived methods. Missing or incomplete comparability studies ranked third in CAP’s deficiency data.

Prevention Strategies

Schedule comparability studies twice yearly with calendar reminders that can’t be overlooked. Define acceptable criteria for comparability before performing studies, not after reviewing results. Include backup instruments in your comparability program. Document studies thoroughly, including the samples used, results obtained, statistical analysis performed, and conclusions reached. When results fall outside acceptable limits, investigate and resolve before returning instruments to patient testing.

6. Equipment Maintenance Documentation Lapses

Why Surveyors Focus Here

Proper equipment maintenance is critical. Surveyors review maintenance logs to verify that preventive maintenance occurs on schedule and that function checks confirm equipment is operating within specifications. Missing records, incomplete logs, or gaps in maintenance schedules suggest equipment reliability may be suspect. This deficiency consistently appears in the top ten across accreditation agencies.

Prevention Strategies

Follow manufacturer maintenance schedules precisely and document every action taken. Retain maintenance records for the required period, typically at least two years. Include documentation of corrective actions when maintenance reveals problems. Use checklists to ensure nothing is missed during routine maintenance. When equipment is out of service for maintenance, document the downtime and how patient testing was handled during that period.

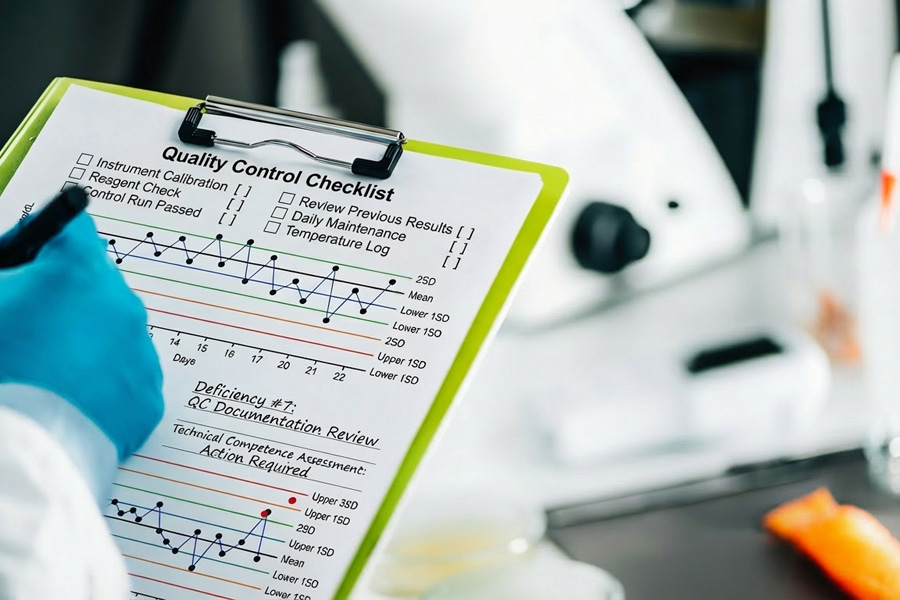

7. Quality Control Documentation Gaps

Why Surveyors Focus Here

Quality control data demonstrates that your testing systems are performing accurately on an ongoing basis. Surveyors expect to see QC performed at required frequencies, results reviewed and evaluated, and appropriate action taken when results fall outside acceptable ranges. Unreviewed QC data, missing statistical analysis, or inadequate corrective actions all generate citations.

Prevention Strategies

Establish clear procedures for QC review, including who reviews, how often, and what constitutes acceptable performance. Generate and review Levey-Jennings charts or equivalent statistical tools to identify trends before they become failures. Document acceptability determinations for every QC event. When QC fails, document the investigation, root cause, corrective action, and verification that the problem was resolved before resuming patient testing.

8. Director Record Review Deficiencies

Why Surveyors Focus Here

CLIA requires laboratory directors or their designees to review quality control, maintenance, and other records at defined intervals, typically monthly. This oversight ensures problems are identified and addressed promptly. Missing monthly reviews or inadequate documentation of reviews set up a red flag, indicating gaps in laboratory oversight. Director review deficiencies consistently rank in the top ten findings.

Prevention Strategies

Calendar monthly review sessions that include all required elements: QC records, maintenance logs, proficiency testing results, and any quality indicators your laboratory tracks. Document reviews thoroughly, including the date, reviewer name, records reviewed, and any issues identified. Even during low-volume periods or holidays, maintain the review schedule. If the director delegates review responsibility, document the delegation and ensure the designee meets qualification requirements.

9. Temperature Monitoring Failures

Why Surveyors Focus Here

Proper temperature control is essential for reagent stability, specimen integrity, and accurate test results. Refrigerators, freezers, incubators, and water baths all require daily temperature monitoring and documentation. Missing daily records, gaps in monitoring logs, or failure to document corrective actions for temperature excursions all trigger citations. This deficiency appeared in CAP’s top ten.

Prevention Strategies

Use calibrated min/max thermometers or continuous monitoring systems for all temperature-controlled equipment. Record temperatures daily, including days when the laboratory is closed if equipment remains in use. Document acceptable ranges for each piece of equipment and take immediate corrective action when temperatures fall outside those ranges. Record what corrective action was taken for any excursion and how you verified the problem was resolved. Consider automated monitoring systems that alert staff to temperature excursions in real time.

10. Corrective Action Plan Weaknesses

Why Surveyors Focus Here

When problems occur, whether PT failures, QC issues, or other nonconformities, your corrective action response demonstrates your laboratory’s commitment to quality improvement. Incomplete corrective action plans, failure to address root causes, or lack of follow-up to verify effectiveness all suggest systemic quality management weaknesses. Strong corrective action processes prevent recurring deficiencies.

Prevention Strategies

Use structured corrective action forms that guide staff through proper documentation: problem description, root cause analysis, immediate corrective action, preventive measures to avoid recurrence, and verification of effectiveness. Address underlying systems issues, not just symptoms. Follow up to confirm that corrective actions actually worked. Track corrective actions over time to identify patterns that might indicate broader quality system issues requiring attention.

Turning Knowledge into Action

Understanding common deficiencies is the first step. Implementing systematic prevention is where most laboratories need support. The deficiencies outlined above share a common thread: they stem primarily from documentation gaps and process inconsistencies rather than direct patient care errors. This means they’re largely preventable with proper systems, training, and oversight.

Laboratory Management Consultants specializes in helping laboratories identify and correct these issues before surveyors arrive. Our mock survey services use current CAP, COLA, and CLIA checklists to evaluate your laboratory exactly as inspectors would. We don’t just identify problems; we help you understand why they’re problems and implement lasting solutions.

For laboratories that have already received citations, our compliance consulting services help develop effective corrective action plans that address root causes and prevent recurrence. We’ve helped hundreds of laboratories move from reactive scrambling to proactive compliance management.

Prepare Now for Spring Inspections

Don’t wait until surveyors are at your door to discover compliance gaps. January is the ideal time to assess your inspection readiness and address any deficiencies while you still have time to implement meaningful improvements.

Contact Laboratory Management Consultants today at (606) 487-0523 or email tpace@emaillmc.com to schedule a mock survey or compliance consultation.

Visit us online at https://laboratorymanagementconsultants.org to learn more about our comprehensive laboratory support services.

With the right preparation and support, your next inspection can be an opportunity to demonstrate excellence rather than a source of anxiety. Let LMC help you turn compliance from a burden into a competitive advantage.

Medica EasyRA

Thermo Fisher Indiko Plus

Abbott ImmTox 270

The 3200 QTRAP system

The Pictus 500